AI-Powered Factory & Lab Concepts for 780 Store Retailer

Company Snapshot:

A family-owned chain of over 780 convenience stores across six states, known for its 24/7 Made-to-Order (MTO) food and beverage menu. They have a strong, loyal customer base and a stated mission to innovate and disrupt its own business model, evidenced by its investment in a technology and innovation hub in Pittsburgh.

Executive Summary

The chain has consistently differentiated itself through a superior food service model and a commitment to customer convenience. This analysis indicates that the next competitive frontier lies in leveraging artificial intelligence to deepen that advantage. Bait Shop’s proposed 'Factory' concepts are designed to drive immediate operational efficiency by using AI to tackle core challenges like food waste, labor optimization, and supply chain accuracy, directly impacting profitability. These initiatives save money and time, freeing up store associates to focus on the 'Total Customer Focus' mission. Concurrently, the 'Lab' concepts offer a strategic roadmap to unlock new revenue streams and fundamentally change the business. By investing in areas like dynamic fuel pricing, AI-powered drive-thru experiences, and generative AI for menu innovation, the retailer can solidify its position as the industry's technology leader. This dual approach—optimizing the present while building the future—provides a clear 'now/next/later' path to enhance the customer experience, boost revenue, and create a more resilient, data-driven organization.

Factory Concept: AI-Powered MTO Ingredient Forecasting

"Minimize food waste and prevent stockouts by using AI to predict demand for Made-to-Order (MTO) ingredients at the store level."

$Cost Reduced : 12 weeks : Supply Chain

Workflow

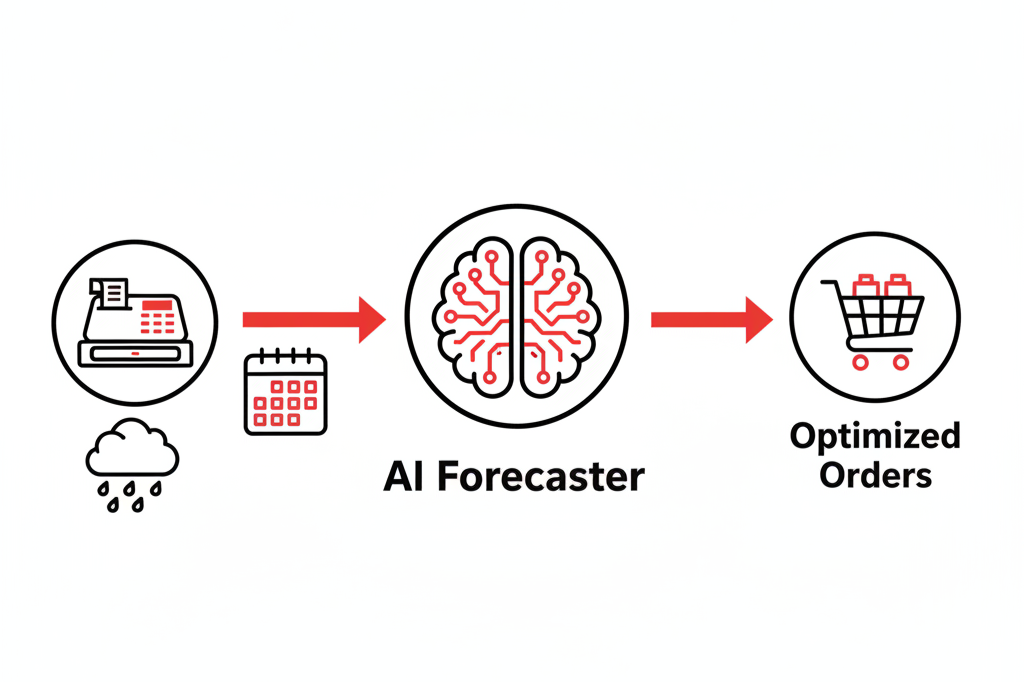

• Input: Historical sales data from POS, real-time store inventory levels, local event calendars, weather forecasts, and traffic patterns.

• Agent Step 1: An AI model analyzes these inputs to forecast demand for specific MTO items (e.g., bread, deli meats, produce) for the next 24-72 hours for each store.

• Agent Step 2: The model compares the forecast against current inventory and existing delivery schedules to identify potential shortages or overages.

• Output: Generates automated, optimized ordering recommendations for store managers, flagging items that need immediate attention.

Integrations

POS System, Inventory Management System, Weather API, Local Events Calendar API

Data Needed

Granular historical sales data for all MTO items, Real-time inventory data, Supplier lead times, Promotional calendar

Risks & Guardrails

Identified Risk: Model inaccuracies could lead to stockouts or continued waste. Guardrail: Implement a 'human-in-the-loop' system where managers must approve AI-generated orders, and continuously retrain the model with new sales data.

Lab Concept: Hyper-Personalized ‘Rewardz' Offers

"Increase purchase frequency and basket size by generating AI-powered, individualized offers for loyalty program members."

$Revenue Lift : 10 weeks : Marketing

Workflow

• Input: Customer's purchase history from the 'Rewardz' program, app usage data, time of day, and preferred store location.

• Agent Step 1: A recommendation engine analyzes individual customer patterns to predict their 'next likely purchase'.

• Agent Step 2: The agent identifies complementary items or upsell opportunities (e.g., a customer who buys coffee every morning might receive an offer for a new breakfast sandwich).

• Output: Delivers a unique, personalized offer or coupon directly to the customer's app, timed for maximum relevance.

Integrations

Rewardz (Loyalty Database), Mobile App (Push Notifications), POS System

Data Needed

Customer transaction history, App interaction data, Offer redemption data

Risks & Guardrails

Identified Risk: Customers feel spammed or that their privacy is invaded. Guardrail: Limit offer frequency and ensure all messaging is opt-in. Be transparent in the privacy policy about how data is used for personalization.

Lab Concept: AI Menu Innovation Machine

"Accelerate the creation of new, successful MTO items by using generative AI to analyze taste trends and customer data."

$Revenue Lift : 22 weeks : F&B

Workflow

Ingest & Normalize: Pull POS orders + modifiers, loyalty/CRM signals, refunds/voids, KDS times, COGS/BOM, store capacity; enrich with seasonality, weather, and public taste trends.

Trend & Flavor Mapper: Detect rising flavors/combos by daypart & region; map to current SKU universe.

Constraint-Aware Generation: Propose MTO builds that obey ops constraints (no new SKUs by default, ≤1 added station step, target ticket time). Auto-draft name, description, and imagery.

Simulation & Scoring: Forecast attach rate, margin, prep load, cannibalization, and supply feasibility; rank with multi-objective score.

Pilot Setup: Auto-package top concepts into A/B tests (price, name, photo variants), select pilot stores, and define KPIs (attach rate, $ margin, ticket time, CSAT).

Deploy & Learn: Push pilots to menus/kiosks/app; monitor in real-time; promote winners to LTO/core and archive learnings to a “recipe memory.”

Integrations

Rewardz (Loyalty Database), Mobile App (Push Notifications), KDS System, POS System

Data Needed

Customer transaction history, Recipe BOM, Social / Google Taste Trends, Weather

Risks & Guardrails

Identified Risk: Allergen/nutrition mislabeling or unsafe prep changes. Guardrail: Human-in-the-loop release gate—culinary + nutrition + QA must approve every AI concept; system blocks any item introducing new allergens or exceeding station/time limits until signed off. Privacy: only aggregated/anonymized customer data is used.